Process capability analysis is a major concept and a must study for professionals looking forward having a firm knowledge on Minitab with Statistics. Minitab is a popular tool that allows one to perform various statistical calculations such as normality test, process capability analysis and so on. Let’s discuss about the same in this post.

What is Process Capability?

Process capability refers to the ability of a manufacturing or production process to produce output that meets specified quality requirements or specifications consistently. In other words, it is a process's ability to deliver results within the desired range of variation.

Process capability is typically measured using statistical techniques, such as control charts and process capability indices. These tools help identify the amount of variation in the output of a process and compare it to the allowable variation specified by the customer or the organization.

It is essential to quality control and improvement in manufacturing and service industries. It helps organizations identify opportunities for improvement, optimize their processes, and ensure that their products or services meet customer expectations consistently.

What is Process Capability Analysis?

Process capability is the ability to produce products or provide services that meet specifications defined by the customer’s needs. As for example: a bottle manufacturer requires that the cap of the bottle should require between 10 and 30 unit of Torque to open the cap of the bottle. Capability analysis reveals how well the manufacturing process meets these specifications, and provides insight into how to improve the process and sustain the improvements.

Process Capability Indices

Process Capability Indices are statistical measures used to assess the ability of a manufacturing process to produce products that meet customer specifications. These indices provide a numerical value that indicates the degree of variation between the process output and the target value or specification limits.

The most commonly used Process Capability Indices are Cp, Cpk, Pp, and Ppk.

- Cp : It measures the potential capability of a process to produce products within specification limits. It is estimated as the ratio of the specification width to the process capability, and a value of 1 indicates that the process can produce products within the specification limits.

- Cpk: It is a similar measure to Cp, but it considers process centering. It considers the process variation and the distance between the process mean and the target value. A Cpk value of 1 or higher indicates that the process is capable of meeting customer specifications.

- Pp: It measures the actual performance of a process relative to the specification limits. It is determined as the ratio of the specification width to the process standard deviation, and a value of 1 indicates that the process can produce products within the specification limits.

- Ppk: It is similar to Pp, but it considers process centering. It considers both the process variation and the distance between the process mean and the target value. A Ppk value of 1 or higher indicates that the process can meet customer specifications.

These Process Capability Indices are essential tools in quality control and process improvement. They allow manufacturers to monitor and improve their processes to meet customer requirements and expectations.

Steps to Conduct Process Capability Analysis in Minitab

- Step 1: Go to File menu, click on Open Project and then load the required data.

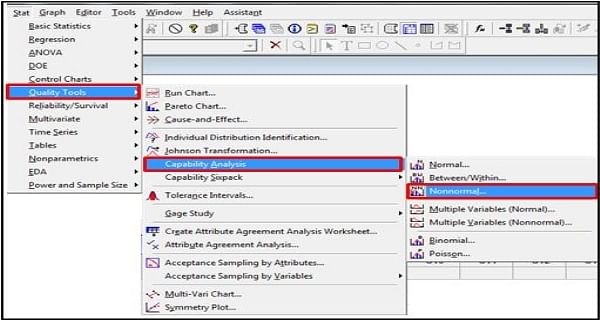

- Step 2: Go to Start menu, move to Quality Tools and then to Capability Analysis.

- Step 3: From the dropdown menu, select Normal or Non Normal analysis based on whether your distribution is normal or non-normal

- Step 4: Click on non-normal (or normal), enter the details required for conducting the capability analysis and then click Ok.

Once we click ok, Minitab generates the process capability in a separate window.

Conclusion

To know more about Process Capability Analysis using Minitab, you can explore Simplilearn’s training courses Lean Six Sigma Green Training certification.

This Lean Six Sigma certification program helps you gain critical skills to lead operational excellence in transformational projects by improving quality and end results.

This course focuses on two important management methodologies – Lean practices and Six Sigma – that can accelerate business improvement.